Back a year or so we saw how the wheels could develop flat spots from sliding along the rail. Those flats pots cause that Whooomp, whoomp, when a train goes by. On a freight car it is relatively simple lifting the car off the wheelset, remove the guilty wheels and axle, replace it or turn it on a lathe. Since the wheels on the axle rotate as a unit both will be flat.

Back a year or so we saw how the wheels could develop flat spots from sliding along the rail. Those flats pots cause that Whooomp, whoomp, when a train goes by. On a freight car it is relatively simple lifting the car off the wheelset, remove the guilty wheels and axle, replace it or turn it on a lathe. Since the wheels on the axle rotate as a unit both will be flat.

But, woe be the engineer that lets flat spots develop on his locomotive. Now you are talking serious issues. The master mechanic and road foreman will have his hide. The loco goes to the back shop, where all the drive wheel/axles must be removed. If one drive wheel has a flat spot, all will because they are connected and work together.

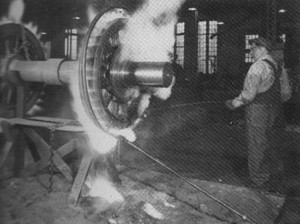

A gas fired ring heats up the tire. You can see the axle is secure in a cradle, and the heat will expand the tire enough for a machinist to sledge hammer it loose. A safety chain will be looped through the spokes. The process is reversed for applying the new tire.

The importance in not allowing the loco to slide along the rails, ever, is best explained by the fact that a train has two sets of brakes. One system is for the locomotive only, the other for the train. A smart engineer will use only the train brakes while operating out on the mainline, and bringing the train to a stop. Once stopped, he can apply the engines to secure the train.

Books have been written on train brakes. The above is only “RR Brakes 101.” – Gary Ostlund, submitted by Jim Futrell.