A scene such as this is bound to bring tears to the eyes of any lover of steam locomotives. Scrapping of the steam fleet provided steady employment for many years in the 50s and 60s.

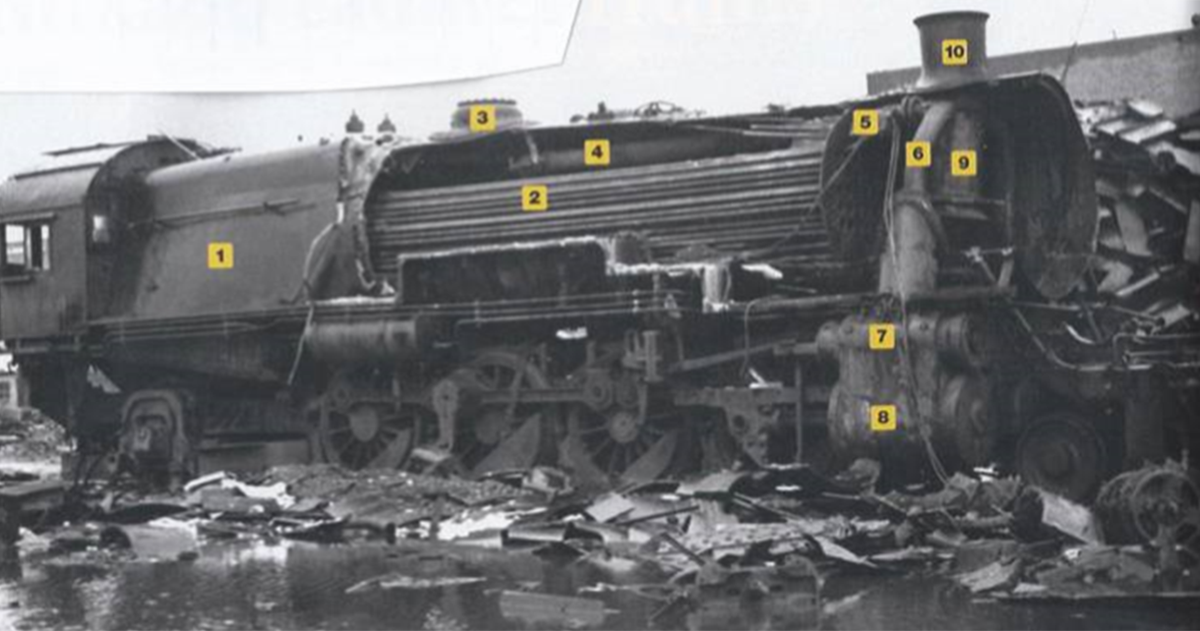

This picture provides a rare view to their inner workings. Pennsylvania Railroad L1s 2-8-2 No. 8280 is being scrapped at Port Newark, N.J. in 1958. With part of its boiler shell cut away, several major internal components are visible, permitting an unintended lesson in the workings of a steam locomotive.

The burning of coal in the firebox (1) produces hot gases. The gases pass through dozens of tubes and flues (2), which are surrounded by water in the boiler. The heat from the gases is transferred to the water, which turned to steam and is collected in the steam dome (3). The throttle valve in the dome regulates the flow of steam to the dry pipe (4), which feeds steam to the superheater (5).

From the superheater, steam delivery pipes (6) lead to the valves (7), which control the admission of steam to the cylinders, it along with the combustion gases from the tubes and flues is exhausted through the petticoat pipe (9) in the smokebox and up the stack (10).

So I guess we could call this “steam locomotive 101.” Thousands of locomotives met such fate as the railroads transitioned to the less labor-intensive diesel. A good many of those scrapped locos were only into the infancy of their working potential. Submitted by Gary O. Ostlund.

Credits: Pix & text in part verbatim from Classic Trains, Summer 2017, Photo by Paul Stephanus