I chased this train up and down the Columbia Gorge, the dates were June 6 and 7, 1997. But my trusty Yashica had finally given up the ghost. My developed Ektachrome slides were all out of focus.

I chased this train up and down the Columbia Gorge, the dates were June 6 and 7, 1997. But my trusty Yashica had finally given up the ghost. My developed Ektachrome slides were all out of focus.

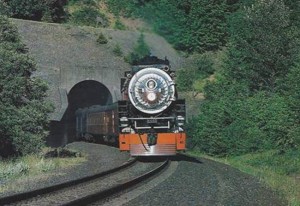

If it hadn’t been for photo stops and preventive stops to check for hot bearings, I would have only seen this train once in each direction. These two days the former ESPEE 4449 was running excursions between Portland, Oregon and Wishram, Washington. The Burlington Northern graciously hosted these runs, and the BNSF continues the practice. The train is traveling on the former Spokane, Portland & Seattle (SP&S) Railway on the Washington side of the Columbia River. Great scenery, good safe access for railfans, Beacon Rock, the Bonneville Dam tunnel, other rock lined tunnels and miles of track parallel to Hwy 14 only a few yards off the fog line. It doesn’t get much better than that, unless all your own slides had developed nicely too. Duh.!

The tunnel here is the result of moving the line further away from the river and dam when the “dam” people built the second powerhouse and bigger & better fish ladder at Bonneville. Lessons learned: a. Not a great idea to chase trains in a motor home, and b. Always have a backup camera. Credit to Gary Ostlund, submitted by James Futrell.

Jim Futrell sent in this shot of a CN hi-rail work truck with the following caption: – McComb Subdivision – Employee Injury – At 0815-27, CN employee had track authority protecting contract workers placing concrete riprap on the lakefront protection levy. The employee was in a hi-rail truck passing a track hoe when the hoe turned and struck the cab of the truck, causing a laceration to his right arm. He had communicated with the workers that he would be passing through the area, but not all employees heard the instructions. EMS transported the employee to North Oaks Medical Center on Ponchatoula, LA, where he underwent surgery and will remain for 7 days.

Jim Futrell sent in this shot of a CN hi-rail work truck with the following caption: – McComb Subdivision – Employee Injury – At 0815-27, CN employee had track authority protecting contract workers placing concrete riprap on the lakefront protection levy. The employee was in a hi-rail truck passing a track hoe when the hoe turned and struck the cab of the truck, causing a laceration to his right arm. He had communicated with the workers that he would be passing through the area, but not all employees heard the instructions. EMS transported the employee to North Oaks Medical Center on Ponchatoula, LA, where he underwent surgery and will remain for 7 days.